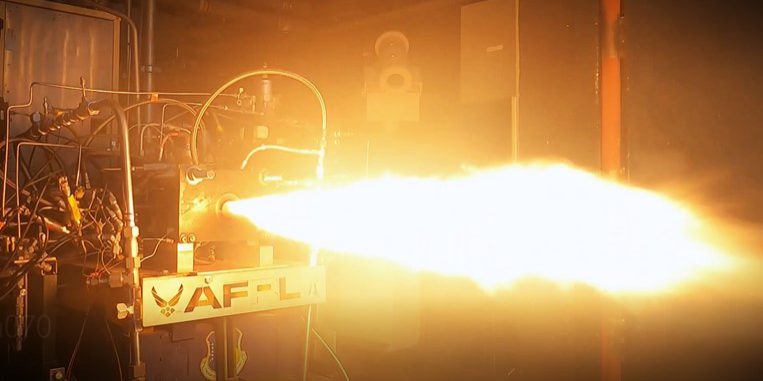

EDWARDS AIR FORCE BASE, Calif. (AFRL) – The U.S. Air Force Research Laboratory, or AFRL, Rocket Propulsion Division, recently designed, printed, built, and hot fired a first-ever, single-block rocket-engine thrust chamber additively manufactured using a process called laser powder directed energy deposition, or DED.

“AFRL’s investments in early advanced manufacturing techniques enable us to exploit corners of the design space for rocket engines and enable faster design turnover cycles from a concept in a whiteboard to test and evaluation in the field,” said Dr. Javier Urzay, Combustion Devices Branch Chief.

DED is an additive manufacturing process in which the device injects metal powder into focused beams of high-power laser in highly controlled atmospheric conditions.