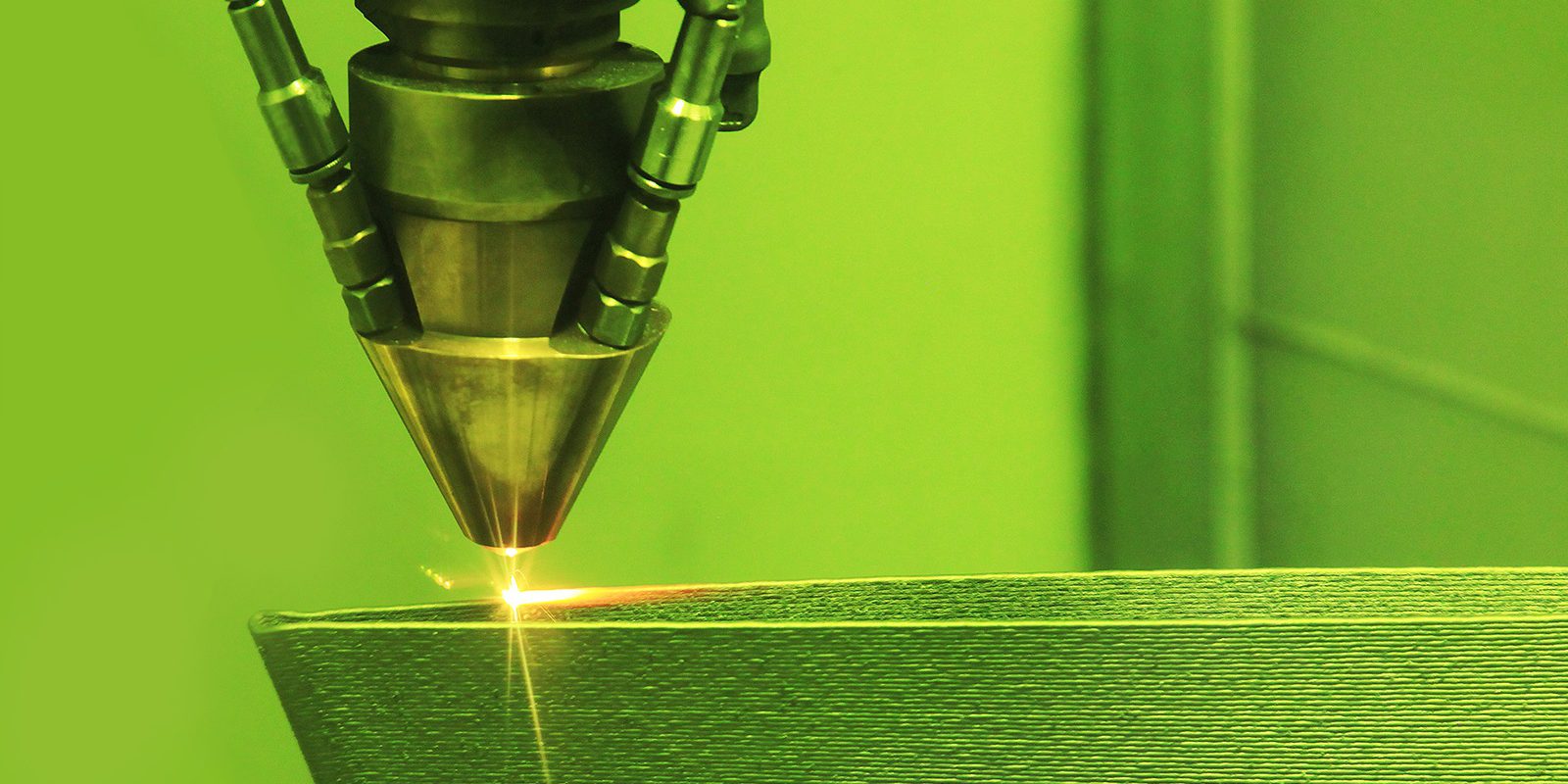

With its ability to yield parts with complex shapes and minimal waste, additive manufacturing has the potential to revolutionize the production of metallic components. That potential, however, is currently limited by one critical challenge: controlling defects in the process that can compromise the performance of 3-D-printed materials.

A new paper in the journal Additive Manufacturing points to a possible breakthrough solution—use temperature data at the time of production to predict the formation of subsurface defects so they can be addressed right then and there. A team of researchers at the U.S. Department of Energy’s Argonne National Laboratory, together with a colleague now at Texas A&M University, discovered the possibility.