an email newsletter released every month highlighting the latest articles, events, technical inquires, and voices from the community

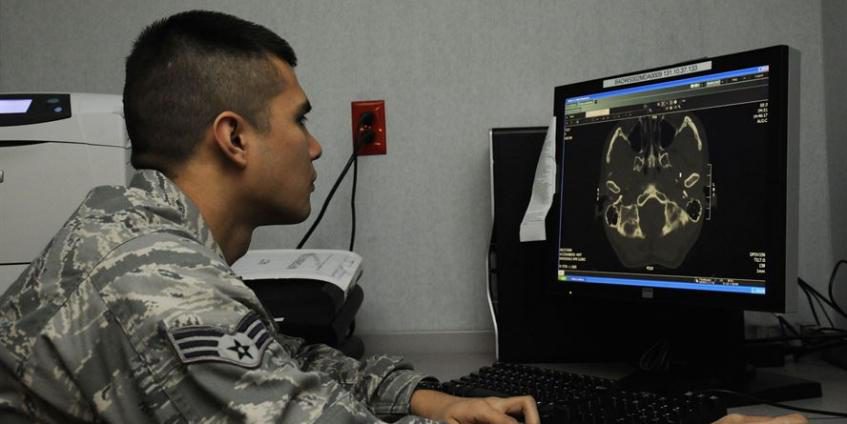

Process Imaging Technologies That Could Benefit Industry

Posted on March 5, 2018 | Completed on July 1, 2017 | By: Scott E. Armistead

What ongoing developments with process imaging are being made within the DoD and other government agencies?

DSIAC staff were asked by Homeland Defense and Security Information Analysis Center (HDIAC) to assist with providing information on process imaging developments within the DoD and other government agencies (OGAs), especially those related to high-energy photon and particle systems, that could potentially be applied to industrial processes. Process imaging includes the use of technologies such as X-ray computed tomography, magnetic resonance imaging and gamma ray tomography, and ultra-sound tomography, as well as new and emerging methods such as electrical capacitance tomography, magnetic induction tomography and electrical resistivity tomography that can be used to non-destructively image and provide associated analytics on production and fabrication processes (e.g., chemical compounding, internal combustion reactions, and quality control of 3D printed metal parts). DSIAC staff subject matter experts (SMEs) compiled information for advanced process imaging efforts within the DoD and OGAs, such as the that from national laboratories. The inquirer was provided a summary of the efforts related to general methodologies/technologies used (X-ray computed tomography, high-speed flash X-ray, synchrotron X-ray phase contrast imaging, neutron imaging, 3D microwave imaging, near infrared spectroscopy, etc.), specific use examples (e.g., aircraft rivet installation, laminar materials/composites defects, wastewater monitoring, weldment monitoring, etc.), and contacts within organizations.

Want to find out more about this topic?

Request a FREE Technical Inquiry!