WRIGHT-PATTERSON AIR FORCE Base, Ohio (AFRL) – The Supersonic Rain Erosion Test Rig (SuRE) at Wright-Patterson Air Force Base is experiencing a full control system replacement and upgrade to provide pinpoint control and unmatched testing value.

The SuRE is used in the evaluation of structures and coatings under the effects of high-speed flight through rain for transonic and supersonic speeds up to Mach 2.3. Various high-speed components and coupon specimens such as radomes, leading-edge materials, and window materials are tested. Data gathered is essential to field feasible material solutions for weapon systems to operate safely under such environmental conditions.

The only other method to reach this speed for component testing is with a rocket sled or flight testing, both of which are expensive and time consuming. The SuRE provides a cost-effective, rapid method to gather data on component performance, tightening the materials development cycle.

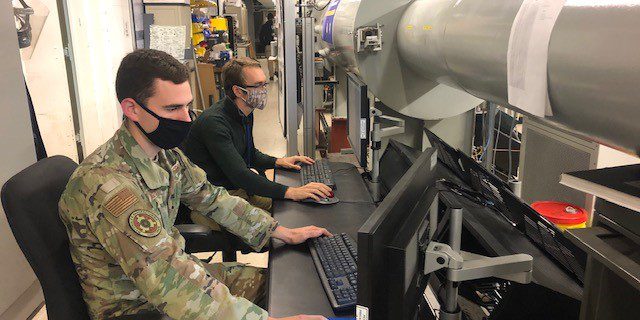

The organic improvements underway include features to introduce flexibility in the executed erosion pattern, replace the current control hardware with a highly adaptable and capable LabVIEW (type of control hardware and software platform from NITM) interface, and automate secondary operations.

Additionally, improvements to the full control system are expected to save approximately $40,000 annually in sustainment cost, reducing the manpower required to run a test by one-third and maintenance downtime by 25%.