an email newsletter released every month highlighting the latest articles, events, technical inquires, and voices from the community

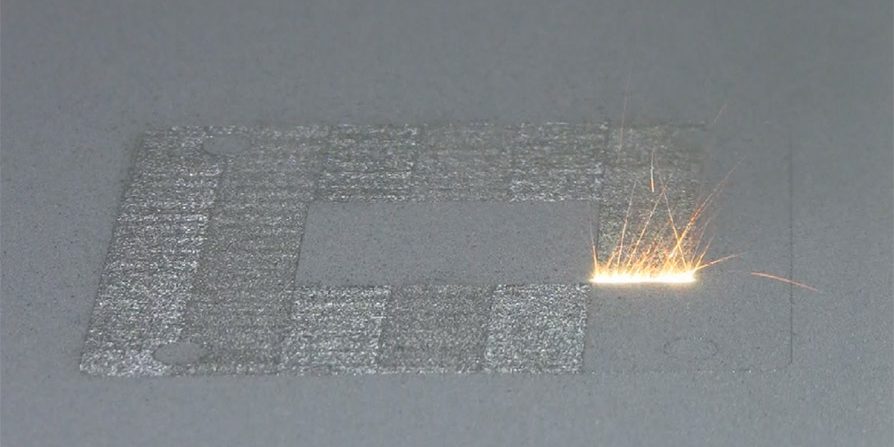

Qualification and Certification of Powder Bed Fusion Additively Manufactured Components

Posted on March 6, 2024 | Completed on August 11, 2023 | By: Travis J. Kneen

What forms of additive manufacturing have been qualified for military use?

Additive manufacturing (AM) is, and has been, a technology gaining traction for replacement parts and optimally designed structures throughout industry. However, with the lack of military or U.S. Department of Defense (DoD)-approved qualification and certification (Q&C) processes (outside of NASA standards), the utilization of AM throughout the Services and DoD certainly isn’t as trusted when compared to traditional manufacturing processes. Potentially due to the lack of such standards for Q&C, many organizations have begun to develop their own guidelines, standards, and best practices. A good summary of current Q&C best practices for metal AM hardware used in aerospace applications from both industry and government perspectives is given in the 2019 Russel et al [1] report in Additive Manufacturing for the Aerospace Industry. This response attempts to consolidate the current perspectives of DoD subject matter experts and reports on the state of Q&C for metallic AM components and processes.

Want to find out more about this topic?

Request a FREE Technical Inquiry!