Introduction

Long-range, gun-launched, high-velocity and hypervelocity projectile (HVP) technologies are highly desired as potential cost-effective solutions for force protection and ballistic missile defense applications. Recently, the Defense Systems Information Analysis Center (DSIAC) conducted an assessment for a DoD customer of historical and current efforts associated with the development and use of high-velocity projectile systems. This article provides a summary of that assessment.

Assumptions, Definitions, and Scope of Research

To begin, it is necessary to understand what exactly is meant by the term “hypervelocity.” The Dictionary of United States Army Terms defines the term as [1]:

- Muzzle velocities of an artillery projectile of 3,500 ft/s or greater.

- Muzzle velocities of tank cannon projectiles in excess of 3,350 ft/s.

For this study, the Defense Systems Information Analysis Center (DSIAC) assumed “hypervelocity” refers to gun-launched munition systems with muzzle velocities exceeding 3,500 ft/s. Other assumptions and/or qualifiers are as follows:

- While the focus of this assessment largely considers mobile land-based and sea-based systems, other technologies are also included for comparison and completeness.

- The literature search emphasizes development activities of the previous 10 years, to focus results on recent and ongoing research efforts.

- Search resources include the Defense Technical Information Center (DTIC), Chemical Propulsion Information Analysis Center (CPIAC) Propulsion Information Retrieval System (PIRS), Internet resources, and personal communications with subject-matter experts.

Technology Overview

Limitations of Current Technology

Most gun technologies can be placed into one of the following four main categories:

- Chemical guns (propellant-based)

- Light gas guns

- Electromagnetic (EM) guns (confined magnetic fields)

- Electrothermal (ET) guns (electrical source external to the gun).

For a conventional solid-propellant (chemical) gun, the constraining factors on performance in terms of muzzle velocity are chamber volume, gun strength, tube length, and the combustion characteristics of the propellant. The gun chamber volume limits the amount of propellant and hence the total available energy; gun strength limits the pressures at which the gun can operate; and tube length affects the expansion ratio. Finally, the burning characteristics of the propellant determine the pressure profiles in the gun.

Due to nonideal effects, such as projectile friction, viscous drag, and heat loss to the wall, the performance of an idealized gun is not generally achieved. However, the parameters that control the performance of any chemical combustion gun are similar. The pressure transmitted from the combustion chamber to the projectile base is largely controlled by the combustion gas sound speed and ratio of specific heats.

Challenges

A number of promising technologies have been, and continue to be, studied to overcome the limitations of current chemical combustion-driven projectile launch systems. Although a great deal of progress has been made, the following are several technical challenges that have plagued these advanced systems. Overcoming these challenges will be key to the eventual implementation of any of the technologies reviewed in this article.

Barrel Wear. Just as conventional gun barrels experience wear with use, EM railgun barrels are not immune to damage, with the leading causes being attributed to the following:

- Arc transition and excessive heating of the rail/armature interface in the breech area of the gun, where projectile velocity is low.

- Hypervelocity gouging of rails by the passage of the armature.

- Erosion of rails near the muzzle due to failure to maintain galvanic contact between the rails and armature.

High G Loads. The extreme g-loading experienced by projectiles requires new materials and design techniques, particularly with regard to electronic components and solid-propellant rocket motors (both case and propellant) for extended-range munitions.

Power Supplies. Many hypervelocity concepts require extremely high levels of pulsed-electrical power for their operation. Compact pulsed power supplies for volume-constrained systems continue to be a challenge, although advancements have been made. Developing cost-effective, compact, lightweight, and efficient pulsed power is one of the most critical challenges faced. High energy-density capacitor development is another area of technological challenge for these systems.

EM Gun Systems

EM Gun. EM guns fall into two basic classes: railguns and coilguns. These guns differ in the geometry of achieving confined magnetic fields and of coupling the resultant forces to achieve projectile acceleration. As a rule, railguns are conceptually and geometrically simpler than coilguns and have lower impedance (i.e., they require higher current and lower voltage for a specific propulsion task). In addition, railguns have received far more developmental attention, even despite the potential for greater energy efficiency that coilguns provide [2].

Railgun. The EM railgun is a long-range weapon that fires projectiles using an electrically induced magnetic field instead of chemical propellants. As illustrated in Figure 1, magnetic fields created by high electrical currents accelerate a sliding metal conductor, or armature, between two rails to launch projectiles at 4,500 to 5,600 mph. In the naval design, electricity generated by the ship is stored over several seconds in the pulsed power system. Next, an electric pulse is sent to the railgun, creating an EM force accelerating the projectile to Mach 7.5 [3].

![Figure 1: The Operation of an EM Railgun [4]. Figure 1: The Operation of an EM Railgun [4].](/wp-content/uploads/2019/11/p18.jpg)

Figure 1: The Operation of an EM Railgun [4].

Coilgun. As with railguns, coilguns also use magnetic forces to accelerate the projectile. However, in a coilgun, these forces are applied inductively and impulsively in a series of distributed coils along the length of the barrel. Coilguns consist of stationary solenoid coils (stators), which create a magnetic field for propelling a moving coil (armature). On paper, these guns seem to overcome many of the disadvantages of railguns. The coilgun requires no sliding contacts, and the muzzle arc frequently seen on railguns is absent. More importantly, a coilgun, being a many-turned device, can have considerably higher inductance than railguns. This fact makes matching to a power supply more convenient [5]. However, large coilguns theoretically require extremely high voltage operation and extremely fast switching.

Electrically Operated Gun Systems

Electric Light-Gas Gun. This gun should not be confused with a two- or three-stage light-gas gun. The only common element is the use of a light gas such as hydrogen. This gun is an extremely high-velocity gun-launch technology. Experimental velocities of 7.2 km/s (23,620 ft/s) with 10% efficiency have been demonstrated for the electric light-gas gun. In theory, this gun should reach velocities in excess of 8 km/s.

Electrothermal (ET) Gun. The ET gun, or electrothermal accelerator, is a propulsion concept in which all or a portion of the energy used to accelerate the projectile is provided by an electrical source that is external to the gun breech. The “pure” form of ET propulsion (as opposed to variations, such as electrothermal chemical) involves the use of electrical energy to create high-temperature plasma, which mixes with and vaporizes an inert working fluid to generate the high-pressure gas needed to accelerate a projectile.

A complete ET gun system comprises four major components. The first component consists of the necessary equipment for generation and storage of the required electrical power. A capillary is then required through which the electrical current (energy) flows, creating a plasma of low mass but extremely high pressure and temperature. This plasma passes into the third component, the combustion chamber, in which the plasma interacts with a working fluid, producing gases that accelerate the projectile through the final component of the system: the gun tube.

An ET gun is limited by similar constraints as those faced by chemical propellant guns. Because an ET gun relies on combustion gases to accelerate the projectile as in a conventional gun, gun strength and tube length will have the same limiting effect as in a solid propellant gun system. The rate and magnitude of the electrical energy input, in combination with the thermochemical properties of the working fluid, determine the pressurization rate and pressure profiles in the gun.

However, the ET gun differs from a conventional solid propellant gun in that chamber volume no longer represents a limitation on the total amount of energy available to the system. In theory, the electrical energy source is capable of providing unlimited energy. However, from an operational point of view, the maximum operating gun temperature limits the amount of energy that can be introduced into the system. In fact, thermal management for an ET gun may be more difficult than for conventional gun systems. For the conventional gun, the overall temperature is bounded by the propellant flame temperature.

Even if the rate of energy input increases due to an increase in the burning rate of the propellant, the maximum gun temperature is still limited to the flame temperature of the propellant. For an ET gun, there is no upper limit on gas temperature. The temperature of the gases resulting from the interaction of the electrically created plasma and working fluid is an increasing function of the amount of electrical energy being transmitted to a unit mass of the working fluid. Thus, temperature limitation results only through controlling the magnitude and rate of electrical energy input in combination with the mass and properties of the working fluid [6].

By using an external power supply to create propellant pressure, ET guns are not bound by the limitations of conventional propellants; energies and velocities can be as high as the structure of the gun will allow [7].

Electrothermal Chemical (ETC) Gun. ETC propulsion is an alternative to conventional methods of firing large-caliber cannon ammunition. In conventional ignition, a relatively low-powered electrical discharge sets off a primer cap that burns a small powder charge within an ignition cartridge, in turn triggering the combustion of surrounding chemical propellant in the round. This sequence of cascaded chemical reactions can take as long as 30 ms to effect projectile motion, with a significant variation in launch times. Consequently, accuracy, particularly when the gun barrel is vibrating due to vehicle motion, is detrimentally affected.

In ETC gun ignition, however, the conventional ignition components are replaced with a plasma injector (as illustrated in Figure 2). The plasma injector houses a bridge wire attached between two electrodes. When a high-current, high-voltage pulse is applied, the bridge wire initiates a high-temperature plasma discharge that vents into the surrounding chemical propellant. The electrically conductive plasma transfers energy into the propellant, initiating its combustion much more quickly and repeatably than does conventional ignition [8].

![Figure 2: The Basic ETC Gun Concept [9]. Figure 2: The Basic ETC Gun Concept [9].](/wp-content/uploads/2019/11/p19.jpg)

Figure 2: The Basic ETC Gun Concept [9].

The ETC gun, which is sometimes called a hybrid gun, is a variation of the ET gun and has demonstrated the same velocity and barrel erosion effects as the ET gun. The main difference between ETC and ET guns is that smaller amounts of electrical energy are required for ETC guns. As the electrical energy is reduced, solid propellants are added; thus, smaller electrical power supplies are needed.

Electrothermal Ignition (ETI) Gun. The term “electrothermal ignition” is sometimes used to refer to ETC at energy levels of less than 100 kJ. ETI provides the same benefits as higher energy ETC, with the exception of thermal compensation for certain propellants, for which levels of 300 kJ or more are required. However, ETI offers precision ignition in a smaller and lighter package, suitable for vehicle integration [8].

Side-Injection Gun. The side-injection gun is enhanced by the accelerating energy coming in from chambers distributed along the barrel. Several different versions of the side-injected gun using ET and electrothermal light gas gun (ELGG) technologies have been built and tested.

Ram Cannon/Ram Accelerators

The ram accelerator is not a gun in the normal sense. As illustrated in Figure 3, its basic operation is more analogous to an inverse ramjet. Instead of confining the combustion gases to a combustion chamber, which then expand to push on the projectile with an ever-decreasing base pressure, they are instead distributed throughout the entire volume of the launch tube. The projectile does not fly ahead of the propelling gases but instead flies through them, basically “surfing” on a wave of high-pressure combustion, which immediately follows the projectile down the bore.

Figure 3: Ram Acceleration Process: Ramjet (upper); Ram Accelerator (lower).

Combustion energy is released dynamically as the projectile flies through the gas, creating a localized region of high pressure immediately behind the projectile, which travels along with the projectile. The gas expends no energy accelerating itself, which thus increases efficiency dramatically and locates the high pressure exactly where it is needed, right behind the projectile, instead of far back in a combustion chamber (as illustrated in Figure 4). Accordingly, traditional gun limitations no longer apply, and velocities in excess of 10 km/s are theoretically possible.

![Figure 4 (bottom): Pressure Profile of Ram Accelerator (lower) Compared to Exponentially Decaying Profile of Conventional Gun (upper) [10]. Figure 4 (bottom): Pressure Profile of Ram Accelerator (lower) Compared to Exponentially Decaying Profile of Conventional Gun (upper) [10].](/wp-content/uploads/2019/11/p20_figure4.jpg)

Figure 4: Pressure Profile of Ram Accelerator (lower) Compared to Exponentially Decaying Profile of Conventional Gun (upper) [10].

Gas Guns

Two-Stage Light Gas Gun (LGG). The two-stage LGG has achieved the highest demonstrated performance to date and has been the standard workhorse for high-velocity experiments for decades. A heavy piston is accelerated in the first stage pump tube by a conventional powder charge or combustion of light gases. This piston then adiabatically compresses a light gas, usually hydrogen restrained by a diaphragm at the beginning of the second stage, which also contains the projectile and barrel. When the compressed hydrogen reaches a threshold value, the diaphragm bursts and the hot, high-pressure hydrogen accelerates the projectile down the barrel. At 7 km/s and greater, such a system is only a few percent efficient and imparts an extremely high initial acceleration to the projectile. Size and barrel design/life issues have precluded the consideration of LGG for weaponization.

Electrothermal Light Gas Gun (ELGG). The ELGG has achieved performance close to that of a conventional LGG and has the potential to exceed it. This gun, which is scalable to large bore sizes, replaces the pump tube structure of the LGG with an electrical power supply. The ELGG uses an electrothermal chamber that is first pressurized prior to a shot with high-pressure hydrogen at about room temperature. A high-powered electric arc pulse is then initiated over the axial length of the chamber, resistively heating the hydrogen and thereby driving the pressure to several kilobars, which bursts a diaphragm and propels the projectile. The peak pressure reached in the chamber depends on the preshot fill pressure, electrical pulse time, projectile mass, and diaphragm burst pressure. In some cases, the prefill hydrogen pressure makes an important energy contribution to the chamber, thereby reducing the electrical energy requirement.

Combustion Light Gas Gun (CLGG)[11].

As shown in Figure 5, the CLGG consists, in its simplest configuration, of a chamber sealed with a diaphragm and filled with a combustible mix of light gaseous propellants such as methane, hydrogen, oxygen, and helium, in various combinations. Prefill pressures can range from a few thousand psi up to 20 kpsi or more. The helium (and hydrogen) acts as a diluent to lower the average molecular weight of the gas. The mixture is ignited using a specially designed ignition system. As the combustion pressure rises, the diaphragm bursts or shears, allowing the projectile to accelerate down bore propelled by the high-pressure, light combustion gases. Note that at 20 kpsi, these gases are near cryogenic liquid density, even though still at room temperature, which is an important factor in generating high pressure at moderate temperature, thus lengthening barrel life.

![Figure 5: Basic CLGG Concept [10]. Figure 5: Basic CLGG Concept [10].](/wp-content/uploads/2019/11/20b.jpg)

Figure 5: Basic CLGG Concept [10].

Single-stage LGGs, by using propellants with low molecular weight, achieve much higher sound speed for a given temperature and are able to achieve considerably higher performance (as shown in Figure 6). In physical terms, the pressures produced in the “combustion” chamber of the LGG are transmitted much more efficiently to the projectile base as the projectile accelerates down bore [10].

Figure 6: Low Molecular Weight Gases Providing Higher Velocities Than Solid Propellants [10].

Extended Range Munitions (ERMs)

ERMs are munitions that are rocket-boosted and use a global positioning system (GPS) guidance system, as opposed to long-range projectiles, which receive all of their kinetic energy in the gun barrel and have no guidance systems. In general, all ERMs operate similarly. The projectile is fired out of a gun, providing its initial kinetic energy. A short time after exiting the gun barrel, the projectile’s stabilizing fins deploy and a solid propellant rocket motor ignites, providing additional boost. As the round flies to its apogee, its guidance package activates and searches for GPS satellites while its steering canards deploy. Once the round reaches apogee and has acquired a GPS signal, its guidance system uses the fins and canards to fly or glide the round directly to its target. The Extended Range Guided Munition (ERGM), Ballistic Trajectory Extended-Range Munition (BTERM), and Long-Range Land Attack Projectile (LRLAP) are all examples of ERMs.

Rocket-Assisted Projectiles (RAPs)

RAPs are specially equipped projectiles with their own source of power in the form of a built-in rocket motor. Such a rocket motor is usually rigidly affixed to the projectile with gas evolved from an ignited propellant, providing additional propulsive force. Ignition of the rocket motor can be accomplished after leaving the gun barrel with a suitably designed ignition system contained within the casing, or ignition can be accomplished by means of the high-temperature gases from the launching charge in the gun barrel.

RAPs provide an incremental improvement in projectile range. For example, General Dynamics’ 155-mm M549A1 HE-RAP extends the range of the standard round from 19.5 km to 30.1 km, a range extension of 54%.

Recent Research Efforts

Gun System Developments

Advanced Gun System (AGS). The Zumwalt-class’s two AGSs are each expected to fire up to 10 rounds per minute, using an automated magazine. As illustrated in Figure 7, the 304-round magazine has to organize and process ammunition and propellant charges from up to 38 pallets. Each pallet holds eight propelling charges and eight of the 230-lb, GPS-guided 155-mm LRLAP shells. The gun can load and fire up to 10 rounds per minute. The AGS ammunition is equivalent to the U.S. Marine Corps (USMC) M198 155-mm howitzer in firepower, and its GPS/Inertial Navigation System (INS)-guided LRLAP is capable of hitting targets accurately up to a distance of 70 to 100 nmi. This performance represents significant improvement over the current 13-nmi range of existing 127-mm/5-inch guns [12].

![Figure 7: AGS Element Overview [13]. Figure 7: AGS Element Overview [13].](/wp-content/uploads/2019/11/p22.jpg)

Figure 7: AGS Element Overview [13].

Office of Naval Research (ONR) EMRG. The EMRG Innovative Naval Prototype (INP) was initiated in 2005. The goal during Phase I was a proof-of-concept demonstration at 32 MJ of muzzle energy, which has been achieved. A future weapon system at this energy level would be capable of launching a projectile 100 nmi.

Phase I was focused on the development of launcher technology with adequate service life, development of reliable pulsed power technology, and component risk reduction for the projectile. Phase II, which started in 2012, will advance the technology for transition to an acquisition program. Efforts will concentrate on demonstrating a rep-rate fire capability. Thermal management techniques required for sustained firing rates will be developed for both the launcher system and the pulsed-power system.

Using its extreme speed on impact, the kinetic energy warhead eliminates the hazards of high explosives in the ship and unexploded ordnance on the battlefield. With its increased velocity and extended range, the EMRG will give personnel a multi-mission capability, allowing them to conduct precise naval surface fire support or land strikes, ship defense, and surface warfare to deter enemy vessels. Navy planners are targeting a 50- to 100-nmi initial capability. A variety of new and existing naval platforms, including the DDG 1000 and DDG 51, are being studied for integration of a future tactical railgun system [14].

The Navy has contracted for and tested two railguns: one built by BAE Systems (see Figure 8) and one built by General Atomics. Both will be put to sea in 2016 for demonstration, but the Navy will choose just one for final testing.

Figure 8: BAE Systems EMRG.

The EMRG’s projectiles have several advantages over the current ERMs in that these projectiles will be smaller, have greater range, and will not require propellants or explosive warheads, which will make the projectiles easier to store and increase the ship’s capacity. It is estimated that a railgun magazine might hold as many as 10,000 rounds using the same 600-round magazine capacity of the AGS.

CLGG. UTRON first developed a 15-mm CLGG, which successfully proved the concept, and then designed and built a 45-mm CLGG, which successfully proved the scalability of the concept [15]. UTRON’s 45-mm CLGG has fired with projectile speeds of 2.5 km/s. In addition, an automatic loader has been developed, installed, and successfully operated. A special fuel-loading system and ignition device have also been successfully developed and deployed. The light-gas propellant mixture can be manufactured on the battlefield.

UTRON then developed and built the 155-mm CLGG that was successfully fired at its gun range in West Virginia. The CLGG has experimentally demonstrated velocities greater than 4 km/s (13,120 ft/s). In some tests, it has demonstrated a muzzle energy increase of 400% when compared to guns with conventional powder propellants. The UTRON CLGG used no large external electrical power supply or conventional powder propellants. It achieved its performance by combusting light gases. Figure 9 illustrates a notional concept for implementing a CLGG and gas production system for a Navy ship. One of the benefits of the CLGG was that it also provided longer barrel life. The UTRON CLGG was designed to fire projectiles to ranges approaching 200 nmi, providing substantial advantages over the current 20-nmi range achievable with traditional powder propellant guns [16].

![Figure 9: Shipboard Arrangement of CLGG Gas Production System [17]. Figure 9: Shipboard Arrangement of CLGG Gas Production System [17].](/wp-content/uploads/2019/11/p23.jpg)

Figure 9: Shipboard Arrangement of CLGG Gas Production System [17].

Line-of-Sight (LOS)/Beyond-Line-of-Sight (BLOS) ETC Launcher. The LOS/BLOS ETC launcher program, funded by the U.S. Army Armament Research, Development, and Engineering Center (ARDEC) at Picatinny Arsenal, NJ, was a comprehensive effort to advance ETC launcher technologies. Objectives of the program were to develop ETC plasma injectors for 120-mm M829A2s, and a 100-kJ pulsed power supply that is small and robust enough to be realistically integrated into a combat vehicle. The program also included the improvement of power connections to the gun to allow electromagnetic field containment and automated connection to the round, as well as tests of the completed ETC system with various chemical propellants and electrical energy levels.

Projectile and Munition Developments

ONR HVP. The HVP is a next-generation, common, low-drag, guided projectile capable of completing multiple missions for gun systems such as the Navy 5-inch, 155-mm, and future railguns. Types of missions performed will depend on the gun system and platform. The program goal is to address mission requirements in the areas of naval surface fire support, cruise missile defense, anti-surface warfare, and other future naval mission areas. Mission performance will vary from gun system, launcher, or ship. The HVP’s low-drag, aerodynamic design enables high-velocity, maneuverability, and decreased time-to-target. These attributes, coupled with accurate guidance electronics, provide low-cost mission effectiveness against current threats and the ability to adapt to air and surface threats of the future.

Rear Adm. Matthew Klunder, Chief of Naval

The high-velocity compact design relieves the need for a rocket motor to extend gun range. Firing smaller, more accurate rounds improves collateral damage requirements and provides potential for deeper magazines and improved shipboard safety. Responsive, wide-area coverage can be achieved using HVPs from conventional gun systems and future railgun systems. The modular design will allow HVPs to be configured for multiple gun systems and to address different missions. The HVP is being designed to provide lethality and performance enhancements to current and future gun systems. An HVP for multiple systems will allow for future technology growth while reducing development, production, and total ownership costs [17].

Excalibur. The M982 Excalibur precision-guided, extended-range artillery shell is a fire-and-forget smart munition with better accuracy than existing 155-mm artillery rounds. These shells are fin-stabilized and are designed to glide to targets with base bleed technology, as well as with canards located at the front of the munition, which create aerodynamic lift. Although the M982 is perhaps the longest-range artillery ammunition in the U.S. arsenal, it has the ability to be fired nearly straight up from positions in cities or hilly terrain, engage its precision-guidance system at high altitudes, and detect and attack moving targets—even individual vehicles—with an accuracy of better than 65 ft from the desired aim point. The shells are guided by GPS signals and inertial measurement units and can be fired from the M109A6 Paladin self-propelled howitzer, as well as from the M198 and M777A2 towed howitzers [18].

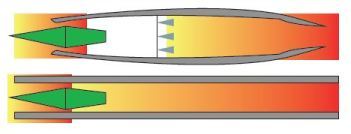

LRLAP. The LRLAP, illustrated in Figure 10, is a 155-mm naval projectile system developed by Lockheed Martin for the next-generation DDG 1000 Zumwalt-class destroyers of the U.S. Navy. It is the Navy’s longest-range projectile. The guided projectile is capable of operating in all weather conditions. It provides off-shore precision fire support, from a safe stand-off distance, to troops deployed in expeditionary assault operations conducted ashore by Marine Corps, Army, and Joint/Coalition forces [19].

![Figure 10: LRLAP Components [13]. Figure 10: LRLAP Components [13].](/wp-content/uploads/2019/11/p24.jpg)

Figure 10: LRLAP Components [13].

LRLAP is part of a family of 155-mm projectiles designed to be fired from the AGS. Because LRLAP has three times the lethality of traditional 5-inch naval ballistic rounds, fewer rounds can produce similar or more lethal effects at less cost. To withstand the punishing gun-launch environment, LRLAP uses g-hardened electronics, including a GPS and INS, to provide a precision munition that maximizes effectiveness and minimizes collateral damage [20].

With DDG 1000 as part of a naval task force or as an independent expeditionary strike force, AGS will launch LRLAP at high velocity from over the horizon to prepare and shape the battlefield. AGS will be capable of a maximum sustained firing rate of 10 rounds per minute to deliver high-volume, 155-mm LRLAP fires at ranges of up to 74 nmi. Each DDG 1000 can mass 140 to 160 projectiles in the air at once and direct multiple-round, simultaneous impact effects against single or multiple targets [21].

Early development of the LRLAP rocket motor proved difficult until lessons learned from previous rocket-assisted, gun-launched systems were incorporated. In addition, since the design was larger than earlier rocket-assisted, gun-launched projectiles, the aerodynamic control surface design required an iterative analysis/wind tunnel test cycle to optimize. This round has also exceeded preliminary cost estimates due to the integration of design improvements during development, but it remains within the acceptable cost target established by the Navy for the AGS.

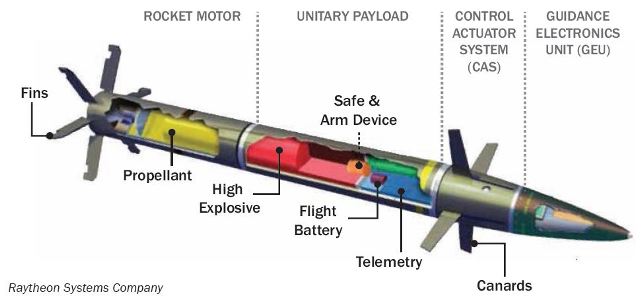

ERGM. The EX-171 ERGM, illustrated in Figure 11, is a 5-inch diameter, precision-guided, rocket-assisted, naval gun projectile. It uses a special high-energy propelling charge intended to achieve a threshold range of 41 nmi from the MK 45 Mod 4, 5-inch/62-caliber gun. The ERGM uses a coupled GPS/INS for guidance and aerodynamic flight control surfaces to steer the projectile to the preselected impact point. The ERGM was intended to provide highly responsive naval gunfire in support of Marine Corps and Army ground combat forces operating ashore, prior to the establishment of organic fire support assets, and to supplement organic field artillery once ashore [22].

Figure 11: The ERGM.

The development of the Extended Range Munition began in 1994, when the U.S. Navy contracted Raytheon to begin developing a long-range, rocket-assisted, precision-guided projectile for the MK 45 5-inch/62-caliber gun. The project eventually took on the title ERGM. After 2 years of research and development, the Engineering and Manufacturing Development phase began in July 1996 when the Navy awarded a contract to Raytheon to develop and produce ERGM or EX-171 as a “low cost” projectile capable of reaching 41 nmi.

The round is fired at a predetermined, fixed target whose location is determined prior to firing. Once the round exits the barrel, eight stabilization fins deploy. Five seconds later, the projectile’s rocket motor ignites, providing the increased boost allowing it to reach a flight apogee of 75,000 to 80,000 ft. As the round travels to its flight apogee, it deploys four control canards, and its navigation system uses GPS data to correct its flight path, allowing it to reach its intended target. As it enters its glide path phase, the round uses an internal measurement unit and the GPS to “fly” or “glide” it to its intended target.

The development of ERGM technology was more difficult than expected, with multiple difficulties arising. The guidance system had to be hardened to withstand the high acceleration force of firing. The development of the canards for the projectile’s aerodynamic design proved functionally and structurally unreliable. Rocket motor development was challenging due to the development of a reliable propellant grain to withstand the gun launch environment as well as the operational requirements. Also, there was a requirement for a new, longer gun barrel that was capable of handling the higher firing energy required by the ERGM [23]. In addition, due to incorporation of the technical improvements to address the development challenges, the estimated cost of this projectile significantly exceeded the “low cost” target established by the Navy. Accordingly, the program was defunded in 2008.

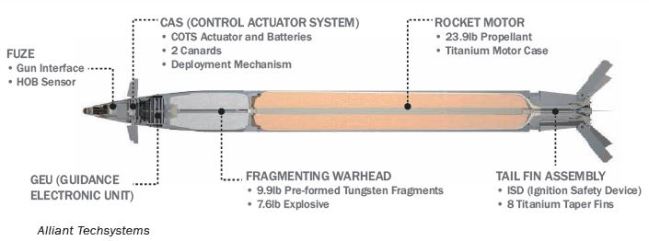

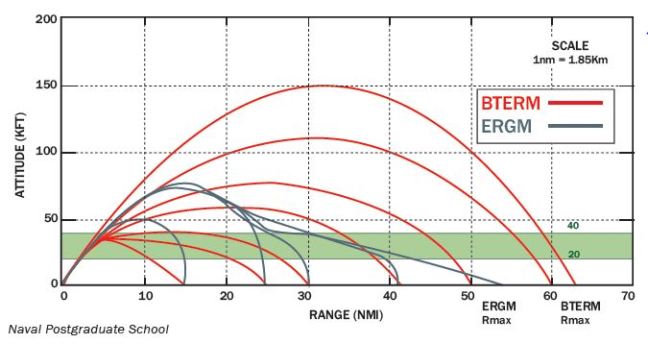

BTERM. Confronted with the high estimated per-round cost of the ERGM, the Navy issued a broad agency announcement for the development of alternative precision-guided munition concepts to the EX-171 ERGM in October of 2003. The Navy stated its projectile target cost of $35,000 or less per unit with a unit cost objective of $15,000. In response, ATK submitted the Autonomous Naval Support Round (ANSR) to the Navy. The program to develop this round was renamed the BTERM, illustrated in Figure 12. BTERM was developed using commercially available components and a minimum of moving parts, following a purely ballistic flight trajectory to reach its target. This design gives the BTERM projectile several advantages: it can get to its target in less time; it uses less airspace to get to the target, thus decreasing airspace deconfliction issues; and it requires fewer in-flight adjustments. In September 2003, a BTERM projectile successfully flew 100 km (54 nmi) in a flight test. However, the BTERM also had its own development problems. In June 2005, a BTERM projectile failed to reach its range objective in a test flight, and although it flew over 79 km (43 nmi), it did not reach the target. Then in October 2005, an unguided BTERM suffered a rocket engine failure [24]. The BTERM’s rocket motor caused test failures that led the Navy to cancel the program and abandon plans to recompete the development contract for extended-range munitions. However, knowledge gained from both ERGM and BTERM has aided the development of later rocket-assisted, gun-launched munitions (see BTERM and ERGM trajectory comparisons in Figure 13).

Figure 12 (top): BTERM.

Figure 13 (bottom): BTERM and ERGM Trajectory Comparisons.

Summary and Conclusions

There have been significant technology development activities over the last 10 years in the area of gun-launched high-velocity and hypervelocity projectiles by university, industry, and government agencies. All gun technologies have had development challenges, with some providing solutions that result in technology readiness levels that would warrant taking the next steps to achieving a deployable land-based mobile platform.

Figure 14 is a comparison of the highest Technology Readiness Level (TRL) technologies, showing the various characteristics of each. As shown, the railgun provides higher energy on target at a much longer range than the ERMs. Its physical characteristics (both weight and length) lend itself to a more mobile platform application, and using electromagnetic energy in place of explosive chemical energy provides for a safer weapon application on a mobile platform. Based upon the data available for high-velocity or hypervelocity gun-launched projectile technologies, the EMRG appears to be the best approach for a sea-based and deployable, land-based mobile platform weapon, providing the required energy on target at the ranges needed. However, adapting EMRG technology to a land-based system the size of a tank may prove unachievable.

![Figure 14: Comparison of Characteristics of Highest TRL Options [22]. Figure 14: Comparison of Characteristics of Highest TRL Options [22].](/wp-content/uploads/2019/11/p27.jpg)

Figure 14: Comparison of Characteristics of Highest TRL Options [22].

In addition, the following excerpt is a conclusion of a study conducted by the Naval Research Advisory Committee in 2004:

Consider the Naval Surface Fire Support (NSFS) mission, which involves primarily indirect fire. The EM gun is the only alternative to expensive missiles or Tactical Air if the Fleet is to support the Marines in Ship-to-Objective Maneuver (STOM). STOM requires ranges in excess of 135 nm. No conventional gun can achieve that range. Furthermore, the railgun offers other attractive options. It would permit gunners to select from a new range of warheads appropriate to different target or different missions—cubes for volume fire, a unitary warhead for hard target, kinetic energy kill, etc. It would also increase usable magazine capacity by 3–5 times the number of rounds over what a ship armed with AGS could carry. Railgun ammunition also offers the prospect of simpler and safer handling and storage. In direct fire applications, including missile defense, anti-ship, and asymmetrical or counter-swarm roles, the railgun should be far more effective than CIWS [close-in weapon system] in terms of projectile pattern and velocity. Railguns might be able to replace current tank main guns in the anti-armor role, and may prove to be the best answer to reactive armor. For all these applications, we find that the electric warship is the key enabler. It can provide the power and can easily accommodate the railgun’s weight and volume. With other platforms we find that volume and weight constraints are far more severe. Meeting these constraints, and handling the thermal loads a railgun generates, in a vehicle the size of a tank presents a considerable challenge [24].

Comparing the characteristics of various projectiles in Figure 14 illustrates that the railgun’s HVP is smaller than the other rounds, so a ship (or a mobile, land-based platform) can accommodate about four times as many rounds in its magazine as it could if it were carrying conventional ammunition. The HVP delivers approximately 17 MJ to a target, and it does so from much greater ranges. The HVP is inert and so poses no explosive threat to its handlers. Hazards of electromagnetic radiation to ordnance, electrostatic discharge, fragment and bullet impact, and cook-off risks would be eliminated, and no unexploded ordnance would remain after a target was serviced. Similarly, since the railgun uses electric current as opposed to burning propellant to accelerate the projectile, no rocket motors or propellant charges would be required [24].

Under Navy and Defense Advanced Research Projects Agency (DARPA) funding, Sandia National Laboratories conducted a study to determine the applicability and maturity of coilgun technology for littoral and strategic strike missions requiring increased range and increased rate of fire on target, using rapid response, cost-effective means. Sandia’s conclusion was that a coilgun system could be developed to meet this requirement, as long as technological development in several critical areas continued. The critical areas identified included high-density capacitor technology for energy storage, barrel structural integrity (mechanical strength, insulation, thermal properties), firing control at full velocity, and projectile terminal maneuvering. It is not known by the author if continued research in these areas has overcome all outstanding issues in the intervening years since Sandia’s study. However, because many of the technological concerns are shared with railgun systems, we can assume that railgun research and development efforts have made major strides toward solutions for coilgun issues as well. In its study, Sandia concluded that a coilgun system designed to fit on a destroyer is feasible, for both fixed and trainable gun types, with projectile ranges and mass in the regions of interest for littoral and inland mission support. Sandia’s coilgun design study found that coils can be designed to meet mission requirements of 100–300 nmi [25].

Numerous technical problems, both of a fundamental and practical nature, remain to be solved before ram acceleration becomes a serious contender in the field of tactical gun propulsion. Understanding, control, and optimization of the fluid dynamics/reaction kinetics in this environment present formidable challenges. Incorporation of this emerging technology into a practical weapon with acceptable safety, reliability, and survivability characteristics as well as performance levels offers even greater uncertainties.

Today’s armed forces face challenges protecting troops and assets in littoral zones and ashore. There is a need to provide supporting fire from longer stand-off ranges, delivered in less time. For example, Naval Surface Fire Support (NSFS) requires a 2–10× increase in the range achievable by conventional naval guns, which are limited to about 12 nmi. Rocket-assisted projectiles have been able to double this range, while extended-range munitions have provided ranges of 40–70 nmi. Ranges approaching and exceeding 100 nmi require a paradigm shift from conventional chemical combustion guns. This paradigm shift will be accomplished using electrically and/or electromagnetically driven projectiles fired from advanced gun systems, such as ONR’s railgun. The challenge remains whether these technologies can be adapted to affordable, mobile, land-based platforms.

Focus of Funding

The Navy continues development of the railgun system and the hypervelocity projectile (for conventional and electromagnetic gun use). The ONR Program Officer for the Hypervelocity Projectile Future Naval Capability (FNC) has verified that development is on course to meet the objective of 2016 sea trials for the railgun systems.

The Army has funded a great deal of research into EM guns over the past several decades, primarily through the Institute for Advanced Technology at the University of Texas at Austin. This research has paved the way for the current ONR program, helping to overcome many of the technological challenges faced by EM guns, including railgun bore life (gouging, arc transition, muzzle blast), novel HVP design with low parasitic mass, advanced pulse alternator technology, and high-g capable electronic components. However, the Army concluded that the railgun was not adaptable to a tank vehicle and suspended funding for EM gun development. Conversations with ONR representatives indicate that the Army is closely watching development of the ONR railgun system to determine if the technology reaches a point where some type of mobile land-based system is achievable.

Future/Ongoing Technology Development Areas

- The following are ongoing development areas:

- Thermal protection materials

- High-temperature-capable alloys

- High-strength advanced composites

- Pulsed power supplies (power, cost, size)

- Component size reduction for mobile application

- High-g capable components.

References:

- U.S. Army. Dictionary of United States Army Terms. Army Regulation 310-25, October 1983.

- May, I., J. Rocchio, et al. “Advanced Gun Propulsion Concepts and Insensitive Munitions Requirements: An Overview of US Efforts.” U.S. Army Ballistic Research Laboratory, Aberdeen Proving Ground, MD; AGARD Conference Proceedings 511, Insensitive Munitions; paper presented at the Propulsion and Energetics Panel 78th Specialists’ Meeting, Bonn, Germany, 21–23 October 1991.

- Office of Naval Research. “Electromagnetic Railgun.” http://www.onr.navy.mil/media-center/fact-sheets/electromagnetic-railgun.aspx, accessed May 2015.

- Fair, H. “Transitioning EM Railgun Technology to the Warfighter.” The University of Texas at Austin, May 2007.

- Bresie, D., and S. Ingram. “Coilgun Technology at the Center for Electromechanics.” The University of Texas at Austin; presented at the 6th EML Symposium, 28–30 April 1992.

- Oberle, W. “Electrothermal Guns – A Theoretical Investigation of Factors for Optimal Performance.” BRL-TR-2999, U.S. Army Ballistic Research Laboratory, Aberdeen Proving Ground, MD, June 1989.

- PowerLabs. “PowerLabs ElectroThermal Gun.” http://www.powerlabs.org/electrothermal.htm, accessed May 2015.

- Dyvik, J., et al. “Recent Activities in Electro-Thermal Chemical Launcher Technologies at BAE Systems.” Presented at the 13th International Symposium on Electromagnetic Launch Technology (EML), Potsdam, Brandenburg, Germany, 22–25 May 2006.

- Byungha, Lee, Kim Jin-Sung, et al. “150 kJ Compact Capacitive Pulsed Power System for an Electrothermal Chemical Gun.” Journal of Electrical Engineering Technology, vol. 7, no. 6, pp. 971–976, 2012.

- Witherspoon , F. D., and D. L. Kruczynski. “Gun Launch to Space – A Discussion of Technology Options.” UTRON, Inc., Manassas, VA, October, 2000.

- http://www.utroninc.com/tech.html, accessed May 2015. Image is found in Source [11]

- “Next-Gen Naval Gunfire Support: The USA’s AGS & LRLAP.” http://www.defenseindustrydaily.com/next-gen-naval-gunfire-support-the-usas-ags-lrlap-07171/, Defense Industry Daily, accessed May 2015.

- ATK. “Long Range Land Attack Projectile (LRLAP).”

- Office of Naval Research. “Electromagnetic Railgun.” http://www.onr.navy.mil/~/media/Files/Fact-Sheets/35/Electromagnetic-Railgun-July-2012.ashx, accessed May 2015.

- UTRON, Inc. “Combustion Light Gas Gun (CLGG): Progress Update Briefing.” 8 April 2008.

- Kruczynski, Massey, et al. “Combustion Light Gas Gun Technology Demonstration.” Final Report for Contract N00014-02-C-0419;, UTRON, Inc., January 2007.

- Office of Naval Research. “Hypervelocity Projectile Program” Data sheet, September 2012.

- Keller, John (editor). “Raytheon to Provide 757 Satellite-Guided Artillery Shells in $51.8 million Army Contract.” Military and Aerospace Electronics, http://www.militaryaerospace.com/articles/2014/07/raytheon-army-excalibur.html, accessed May 2015.

- Naval-Technology.com “Long Range Land Attack Projectile (LRLAP), United States of America” http://www.naval-technology.com/projects/long-range-land-attack-projectile, Naval-Technology.com, March 2014 accessed May 2015.

- Lockheed Martin. “LRLAPTM: Long Range Land Attack Guided Projectile for the U.S. Navy.” http://www.lockheedmartin.com/content/dam/lockheed/data/mfc/pc/LRLAP/mfc-lrlap-pc.pdf, accessed May 2015.

- BAE Systems. “155-mm Long Range Land Attack Projectile (LRLAP).” http://www.baesystems.com/product/BAES_020036/155-mm-long-range-land-attack-projectile-lrlap, accessed May 2015.

- Office of the Secretary of Defense, Director, Operational Test and Evaluation. “EX-171 Extended Range Guided Munition (ERGM),” http://www.dote.osd.mil/pub/reports/FY2002/pdf/navy/2002EX-171ERGM.pdf, accessed May 2015.

- Wahl, Douglas. “Increasing Range and Lethality of Extended-Range Munitions (ERMs) Using Numerical Weather Prediction (NWP) and the AUV Workbench to Compute a Ballistic Correction (BALCOR).” Master’s Thesis, Naval Postgraduate School, Monterey, CA, December 2006.

- Naval Research Advisory Committee. “Electromagnetic (EM) Gun Technology Assessment.” Arlington, VA, February 2004.

- Shope, S., et al. “Results of a Study for a Long Range Coilgun Naval Bombardment System.” Sandia National Laboratories, Albuquerque, NM; presented at the 10th U.S. Army Gun Dynamics Symposium, Austin, TX, 23–26 April 2001.

![Figure 6: Low Molecular Weight Gases Providing Higher Velocities Than Solid Propellants [10].](/wp-content/uploads/2019/11/plot-P21-400x277.jpg)