an email newsletter released every month highlighting the latest articles, events, technical inquires, and voices from the community

Cryogenic Treatments for Sniper Rifle Barrels

Posted on April 23, 2019 | Completed on February 1, 2019 | By: Doyle T. Motes III

What research has been done in cryogenic barrel treatments for sniper barrels in order to improve accuracy and barrel life?

The Defense Systems Information Analysis Center (DSIAC) received a technical inquiry requesting information on research, subject matter experts (SMEs), and points of contact with experience in cryogenic treatment of steel for sniper rifle barrels. A DSIAC SME from the Texas Research Institute at Austin (TRI Austin) performed a literature search in the Defense Technical Information Center and also searched various repositories for materials science papers and vendors offering cryogenic treatments to owners and operators of various forms of firearms. The results of the TRI Austin SME’s search were summarized and delineated in a response report.

1.0 Introduction

The inquirer requested information on existing research and subject matter experts (SMEs)/points of contact (POCs) that have or are working in cryogenic barrel treatments for steel alloy sniper rifle barrels. The process involves cooling the barrels to minus 300 °Fahrenheit (F), and the purpose is to increase rifle accuracy and improve barrel life. The inquirer was also interested in the cost of this process.

The Defense Systems Information Analysis Center (DSIAC) received support from an SME from Texas Research Institute Austin (TRI Austin), Mr. Doyle T. Motes, P.E., who has a number of years of experience in internal ballistics and materials science. DSIAC and TRI Austin completed a literature search using the Defense Technical Information Center Research and Engineering Gateway, open sources, university libraries, and vendors offering the cryogenic treatment.

1.1 Claims Associated with Cryogenic Treatment

All gun barrels produced today are first heat treated to a certain temper to provide the desired mechanical properties for the steel being used, as determined by the firearm manufacturer and based on the end use of the barrel. (Rifle barrels launching heavier projectiles require higher base pressures and more stringent material properties than handguns launching lighter projectiles.) After the barrel is heat treated, it is machined (boring of the barrel’s internal channel). Machining is done after heat treatment because the heat treat process can slightly change the dimensions of the raw materials. Other operations produce barrels from forgings or castings that cool at different rates. The result of either of these fabrication processes is the introduction of residual stresses into the barrel.

The following excerpt from “Firearms and Gun Barrels” discusses the cryogenic treatment for a gun barrel [1]:

Cryogenic barrel treatment utilizes liquid nitrogen to bring the temperature of the gun barrel down to -300°F. The gun barrel is kept at this level for 24 hours to relieve residual stresses created during manufacturing. Cryogenic treatment is a one-time, permanent process. The improvement lasts the entire life of the gun or rifle.

Several shotgun manufacturers have incorporated cryo treatment in their manufacturing processes. They found that the shot groupings of non-treated guns shifted as much as 10″ to 12″. After the same gun was cryogenically treated, the groupings shifted less than 1″ (.075″). Therefore, accuracy is always dramatically improved after cryogenic treatment. (See BenelliUSA for more information.)

As mentioned in the excerpt, Benelli can offer additional information on cryogenic treatment for a gun barrel, specifically on their “Crio System” [2]. The claims made by this Benelli vendor are similar to those of others including the following mentioned in another excerpt from “Firearms and Gun Barrels” [1]:

When fired, a gun barrel heats up and distorts or warps every time the trigger is pulled. This distortion results in lost accuracy.

By cryogenically treating the gun barrel, you will see immediate results:

- Increased wear resistance for easier cleaning.

- Reduced friction, heat and wear for an improved barrel life.

- Improved shot groupings resulting in improved accuracy.

- Increased velocity of about 50–60 feet per second.

Recently, Nitrofreeze cryogenically treated 19 Remington 700 Light Tactical Rifles for the Maine State Police for improved accuracy in hostage situations.

1.2 Proponents and Detractors of Cryogenic Treatment

The cryogenic treatment described in “Firearms and Gun Barrels” [1] is a commonly cited accurizing treatment for gun barrels. The proponents of this process claim it increases the accuracy (decreases the shot dispersion) of barrels subjected to this treatment. There are numerous online forums and discussion boards where firearm owners and operators discuss the effects and advantages of cryotreating barrels. The groups are often divided into three roughly equal groups (by number of postings): proponents of cryotreating, detractors of cryo-treating, and those simply seeking information on cryotreating (both what it entails and its effectiveness).

The following excerpt from “How Are Gun Barrels Enhanced?” provides information on proponents of cryotreatments [3]:

Proponents of cryogenic treatment claim that it removes stresses, changes the grain structure, stabilizes the barrel so that it will not warp as it heats up, increases accuracy, improves barrel life and reduces metal fouling. Proponents also note that the process is relatively inexpensive.

Detractors cite independent testing of the process by major manufacturers, which has not been able to identify increases in firearm accuracy. However, the process has been shown to result in easier machining and greater wear resistance in steels that tend to have significant amounts of retained austenite (a microstructural constituent of steel), such as stainless steels, but cryo-treatments do not appear to significantly affect the accurate life of stainless steel (416R alloy) barrels. Metallurgists quoted by the National Rifle Association (NRA) state that a cryogenic treatment can only remove about 6% of the residual stress within a barrel after boring. The NRA conducted its own tests comparing cryotreated and non-cryotreated barrels and found that the treatment modestly improved the accuracy in some barrels (10% or less), and there was no increase in the accuracy of others [3].

Research conducted by Sierra Bullets and reported in Precision Shooting Magazine in 1998 showed that in a controlled test, there was little benefit to deep freezing match-grade barrels. A difference in accuracy was not identified, but there was a slight increase in useful barrel life [4].

1.3 Materials Science Behind Cryotreatments

Cryogenic treatments were first commercialized in the mid to late 1960s [5]. The following excerpt from “An Introduction to Cryogenic Hardening” describes the process of cryogenically treating a metal part [5]:

The process of cryogenically treating a metal part involves very slowly cooling the metal using a gaseous liquid nitrogen. The slow cooling process from ambient to cryogenic temperatures is important in avoiding thermal stress.

The metal part is then held at a temperature of around −190 °C (−310 °F) for 20 to 24 hours before heat tempering takes the temperature up to around +149 °C (+300° F). This heat-tempering stage is critical in reducing any brittleness that may be caused due to the formation of martensite during the cryogenic treatment process.

Cryogenic treatment changes the entire structure of a metal, not just the surface. So the benefits are not lost as a result of further processing, such as grinding.

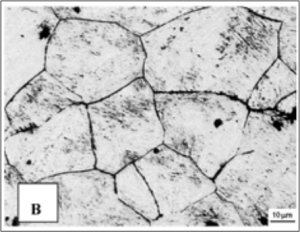

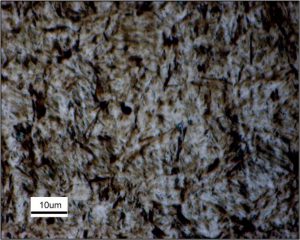

Cryogenic treatments can substantially benefit the mechanical properties of certain steels, provided that they retain some austenite (γ-Fe, with a face-centered cubic crystal structure, shown in Figure 1) at room temperature after the initial heat treatment. The cryogenic treatment increases the amount of martensite (which has a body-centered tetragonal crystal structure, shown in Figure 2) within the microstructure of the steel that increases the strength and hardness, but this is sometimes at the cost of the toughness. This issue can be mitigated to different extents by a post-cryoheat treatment at elevated temperatures [6].

The transformation from austenite to martensite is primarily accomplished through quenching, but in general, it is driven farther and farther toward completion as the temperature decreases. In higher-alloy steels such as austenitic stainless steels, the onset of transformation can require temperatures much lower than room temperature. More commonly, an incomplete transformation occurs in the initial quench, meaning that cryogenic treatments merely enhance the effects of prior quenching. However, since martensite is a nonequilibrium phase on the iron-iron carbide phase diagram, it has not been shown that warming the part after the cryogenic treatment results in the retransformation of the induced martensite back to austenite or to ferrite plus cementite, negating the hardening effect [6].

Figure 1: A Microstructural Image of Austenite in SAE 4340 Steel (Also a Chromium-Molybdenum [Cr-Mo] Steel). Note the Lack of the Needle-like or Lath Structure That Is Associated With the Presence of Martensite [7].

Figure 2: A Microstructural Image of Martensite (Showing a Typical Lath Structure) in AISI 4140 Steel (a Common Cr-Mo Steel That Can Be Used in Gun Barrels) [6].

The transformation between the austenite and martensite phases is instantaneous and not dependent upon diffusion, meaning that cryogenic treatment causes a more complete hardening rather than moderating extreme hardness; therefore, the term “cryogenic tempering” is technically incorrect. Research has shown that a cryotreatment precipitates fine-sized η-carbides within the crystal matrix, which imparts very high wear and corrosion resistances to the bulk material.

In terms of the bulk materials, a cryogenic treatment of certain metals is known to provide three beneficial effects, which are identified in the following excerpt from “An Introduction to Cryogenic Hardening” [5]:

- Greater Durability: Cryogenic treatment helps to promote the transformation of retained austenite present in heat-treated steels into harder martensite steel. This results in fewer imperfections and weaknesses in the steel’s grain structure.

- Improved Wear Resistance: Cryogenic hardening increases the precipitation of eta-carbides. These are fine carbides that act as binders to support the martensite matrix, helping to resist wear and corrosion.

- Stress Relief: All metals have residual stress that is created when it solidifies from its liquid phase into a solid phase. These stresses can result in weak areas that are prone to failure. Cryogenic treatment can reduce these weaknesses by creating a more uniform grain structure.

The cryogenic treatment process is very effective in enhancing heat-treated martensitic steels, such as high carbon and high chromium steels, as well as tool steels [6]. A review of cryogenic treatments for steels is provided in the article “A Research Review on Deep Cryogenic Treatment of Steels” [9]. Detailed and specific engineering descriptions of the cryogenic treatment process can be found in the following documents:

- “Cryogenic Treatment and its Effects on Tool Steel” by T. Yugandhar et al. [10].

- “Cryogenic Treatment of Steel: From Concept to Metallurgical Understanding” by M. Villa and M. Somers [11].

- “Cryogenic Processing—Dispelling the Myths, Mysteries” by E. Lundin [12].

- “Optimization of Deep Cryogenic Treatment to Reduce Wear Loss of 4140 Steel” by D. Senthilkumar and I. Rajendran [13].

Cryogenic hardening can also be used to treat other materials, which are identified in the following excerpt from “An Introduction to Cryogenic Hardening” [5]:

Besides steel, cryogenic hardening is also used to treat cast iron, copper alloys, aluminum, and magnesium. The process can improve the wear life of these types of metal parts by factors of two to six.

1.4 What Can a Cryotreatment Provide?

Cryogenic treatments can improve the mechanical properties of various steels. However, the effects of cryogenic treatments on gun barrels are disputed. There appear to be no disadvantages associated with cryogenically treating gun barrels, and in fact, wear and corrosion resistance are increased, but advantages have not been shown to extend to increased accuracy or muzzle velocity [4].

The owner of Lilja Precision Rifle Barrels, Inc. (a manufacturer and fabricator of custom rifle barrels) has discussed this topic previously. The following is an excerpt of his response to the question “What is your opinion of the deep cryogenic processing of barrels?” [14]:

The cryogenic treating of barrels at a temperature of -300 degrees below zero has been a hot topic of discussion lately. Our short answer is that it will not harm your barrel, but we are not completely convinced of all of the benefits claimed by some. The only benefits that we feel are likely to result from the treatment are possibly a longer barrel life and a slight increase in machinability.

Claims for increased accuracy through stress relief are not founded in our opinion. When barrels are button rifled no material is removed, it is just displaced. This causes stresses to be formed in the steel. If these stresses are not removed problems will result. These negative conditions include warping of the barrel during other machining operations, an increase in the bore diameter towards the muzzle end of the barrel during the contouring phase, and in the extreme, lengthwise splitting of the barrel. Also, if there are stresses remaining in the barrel they can be slowly released as a barrel warms up during firing. This causes the barrel to actually move during the course of shooting, causing inaccuracy.

In our testing we have found that the only effective means to completely remove the types of stresses introduced during rifling are with conventional heat treating using elevated temperatures. The -300 degree treatment alone will not remove these stresses. We have been told by a knowledgeable metallurgist that the deep cold treatment will, at best, remove up to 6% of the remaining stresses in the type of steel used for rifle barrels. The key words here are remaining stresses. In other words, if the barrel was not stress relieved conventionally, then only 6% of the original stress will be removed. If the barrel has been treated conventionally with heat and then brought through the -300 degree cycle, up to 6% of any remaining stresses could be removed by the cold treatment. We do know through our testing that the cold treatment alone will not remove any significant amount of stress and that the problems outlined above concerning stress will remain in the barrel.

So, because of the very limited amount of stress that could be removed with the cold treatment (if the barrel has been properly stress relieved with heat as our barrels are), we do not believe that there can be much if any accuracy benefit to the -300 degree treatment of our barrels. It is for these reasons that we feel the cold process has very little potential for increasing the accuracy of our barrels. In our opinion, other than the removal of these stresses, there are no other mechanical factors involved that could benefit accuracy in a rifle barrel, resulting from a heat-treating operation, either hot or cold.

For reasons not completely understood, however, there may be an increase in the wear resistance of the steel. This type of wear, however, does not contribute greatly to barrel erosion. We invite you to read our comments on this type of barrel wear in the question regarding the use of moly-coated bullets.

Another possible side benefit to the freezing process is a slight increase in its machinability.

2.0 Summary and Conclusions

The topic of cryogenic treatments for firearm barrels (regardless of the type) is contentious. There are several vendors and operators that claim that this treatment is 1) exceedingly useful to increase barrel life; 2) makes the barrel easier to clean; 3) potentially increases muzzle velocity; and 4) increases accuracy (as the treatment decreases shot dispersion on a target). However, a large group of manufacturers, scientists, and operators claims that cryogenic treatment does not provide any substantial benefit to firearm barrels, but they note that it will not necessarily harm the barrel and may make machining easier. It may also impart wear and corrosion resistance.

Although there is ongoing research in the material science and processes behind cryogenic treatments for a wide range of steels, specific research into cryogenically treating firearm barrels (specifically sniper barrels) does not appear to be ongoing.

Section 2.1 provides a list of barrel fabricators/operators [15–19]. The cost of cryogenically treating firearm barrels is affordable, usually less than $100 per barrel, although the cost does vary depending on the vendor [20–22]. Section 2.2 lists cryogenic treatment operators.

2.1 Barrel Fabricators

The following is a list of barrel fabricators that can be contacted:

- Lilja Precision Rifle Barrels, Inc. [15].

- Website: http://riflebarrels.com/ .

- Phone: 406-826-3084.

- McGowen Precision Barrels, Inc. [16].

- Website: http://mcgowenbarrel.com/.

- Phone: 406-552-1146.

- Shilen Rifles, Inc. [17].

- Website: http://www.shilen.com/index.html.

- Phone: 972-875-5402.

- Schneider Rifle Barrels, Inc. [18].

- Website: http://schneiderriflebarrels.com/.

- Phone: 928-474-2852.

- Hart Rifle Barrels [19].

- Website: https://www.hartbarrels.com/.

- Phone: 315-677-9841.

2.2 Cryogenic Treatment Operators

The following is a list of cryogenic treatment operators that can be contacted:

- Nitrofreeze Cryogenic Solutions, Inc. [20].

- Website: http://nitrofreeze.com/.

- Phone: 800-739-7949.

- 300 Below Cryogenic Tempering Services, Inc. [21].

- Website: https://www.300below.com/firearms-cryo-barrel/.

- Phone: 800-550-2796.

- Diversified Cryogenics, Inc. [22].

- Website: https://www.diversifiedcryogenics.com/gunbarrels.html.

- Phone: 888-323-8456.

References

[1] Nitrofreeze Cryogenic Solutions. “Firearms and Gun Barrels.” http://nitrofreeze.com/ services/conventional-cryogenic-treatment/firearms-gun-barrels/, accessed 15 February 2019.

[2] Benelli. “Crio System.” https://www.benelliusa.com/crio-system, accessed 15 February 2019.

[3] NRA Staff. “How Are Gun Barrels Enhanced?” NRA Family, https://www.nrafamily.org /articles/2018/2/6/how-are-gun-barrels-enhanced/, February 2019.

[4] Thomas, K. “Sierra Bullets Analysis of Cryogenic Treatment for Barrels.” Precision Shooting Magazine, 1998.

[5] Bell, T. “An Introduction to Cryogenic Hardening.” The Balance, https://www.thebalance. com/ cryogenic-hardening-2340006, 6 January 2019.

[6] Wikipedia. “Martensite.” https://en.wikipedia.org/wiki/Martensite, 4 February 2019.

[7] Ajus, C., S. S. M. Tavares, M. R. Silva, and R. R. A. Corte. “Magnetic Properties and Retained Austenite Quantification in SAE 4340 Steel.” Materia, vol. 14, no. 3, Rio de Janeiro, https://www.researchgate.net/publication/250049131_Magnetic_properties_and_retained_austenite_quantification_in_SAE_4340_steel, January 2009.

[8] Wikipedia. “Cryogenic Hardening.” https://en.wikipedia.org/wiki/Cryogenic_hardening, 5 February 2019.

[9] Senthilkumar, D., and I. Rajendran. “A Research Review on Deep Cryogenic Treatment of Steels.” International Journal on Materials and Structural Integrity, vol. 8, no. 1-3, pp. 169–184, https://www.researchgate.net/publication/260656346_A_research_review_on_deep_cryogenic_treatment_of_steels, October 2014.

[10] Yugandhar, T., P. K. Krishnan, C. V. Bhaskar Rao, and R. Kalidas. “Cryogenic Treatment and its Effects on Tool Steel.” Proceedings of the 6th International Tooling Conference, pp. 671–684, 2002.

[11] Villa, M., and M. Somers. “Cryogenic Treatment of Steel: From Concept to Metallurgical Understanding.” Proceedings of the 24th IFHTSE Congress, 2017 European Conference on Heat Treatment and Surface Engineering, https://www.researchgate.net/publication/ 318112266_Cryogenic_treatment_of_steel_from_concept_to_metallurgical_understanding, June 2017.

[12] Lundin, E. “Cryogenic Processing—Dispelling the Myths, Mysteries.” The Tube & Pipe Journal, https://www.thefabricator.com/article/shopmanagement/cryogenic-processingadispelling-the-myths-mysteries, 15 March 2013.

[13] Senthilkumar, D., and I. Rajendran. “Optimization of Deep Cryogenic Treatment to Reduce Wear Loss of 4140 Steel,” Journal of Materials and Manufacturing Processes, vol. 27, no. 5, pp. 567–572, https://www.tandfonline.com/doi/abs/10.1080/10426914.2011.593237, 2012.

[14] AZURO. “Wondering About Cryo Treatment.” http://benchrest.com/archive/index.php/t-88487.html, accessed March 2019.

[15] Lilja Precision Rifle Barrels. http://riflebarrels.com/, accessed February 2019.

[16] McGowen Precision Barrels. http://mcgowenbarrel.com/, accessed February 2019.

[17] Shilen Rifles, Inc. http://www.shilen.com/index.html, accessed February 2019.

[18] Schneider Rifle Barrels, Inc. http://schneiderriflebarrels.com/, accessed February 2019.

[19] Hart Rifle Barrels. https://www.hartbarrels.com/, accessed February 2019.

[20] Nitrofreeze Cryogenic Solutions. http://nitrofreeze.com/, accessed February 2019.

[21] 300 Below Cryogenic Tempering Services, Inc. “Cryo-Accurizing – Rifle, Shotgun, and Firearm Barrel Cryogenic Stress Relief and Stabilization.” https://www.300below.com/, accessed February 2019.

[22] Diversified Cryogenics. “Gun Barrels.” https://www.diversifiedcryogenics.com/ gunbarrels.html, accessed February 2019.

Want to find out more about this topic?

Request a FREE Technical Inquiry!